Exploring the benefits of oil mist collectors

It is a good idea to get oil mist collectors for your industrial facility. They will be able to help you with reducing overall downtime and maintenance effectively. On top of that, you can ensure the safety of CNC machines as well as ensure employee health. There are some government regulations that you will need to adhere to as you manage an industrial facility. You can adhere to all of them with the help of oil mist collectors. While keeping that in mind, let’s deep dive and explore the key benefits that oil mist collectors are capable of delivering to you.

- You can ensure overall safety at an industrial facility

Oil mist collectors help overall shop safety in the same way. Oil mist may escape even in enclosed CNC router when the door is opened when loading raw materials or withdrawing completed components, causing overall workplace safety problems.

When oil mist escapes off CNC milling, it settles on neighboring surfaces such as walls, countertops, floors, and lights in a machine shop. Oil mist on lights makes the business darker, and oil on other surfaces necessitates additional cleaning3. Not only does this raise issues about cleanliness, but oil on the floor may also provide a slipping danger. Oil mist, but at the other hand, generates a combustible line of oil on the ground and other surfaces, posing a fire threat.

- You can effectively reduce downtime and maintenance

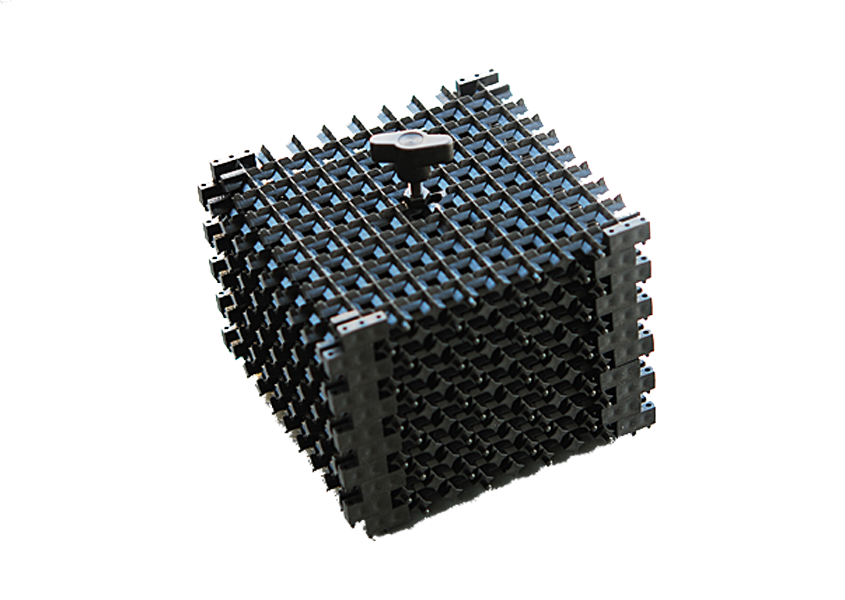

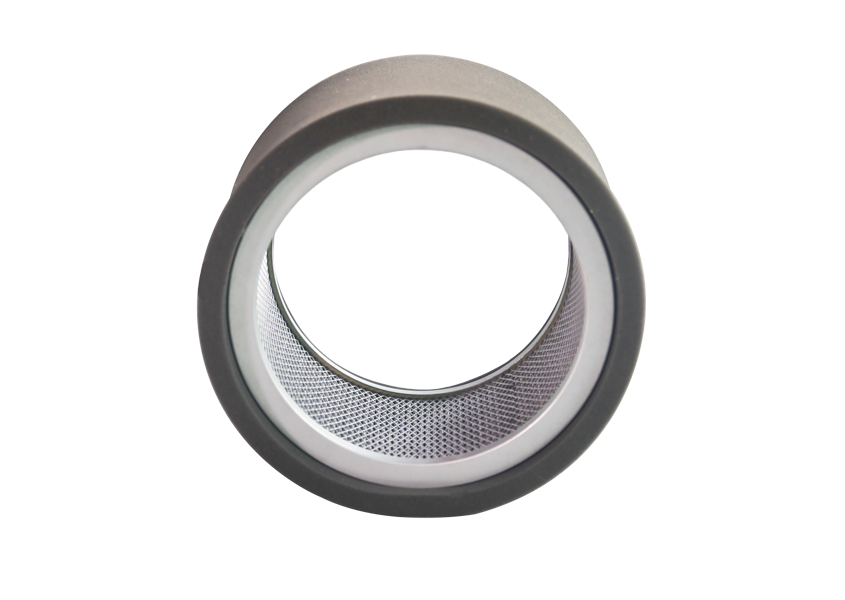

CNC machines benefit from oil mist collectors because they save maintenance and downtime. Components like as cooling system filters, control panels, and fans get contaminated when CNC machines lack adequate mist collectors, causing typical and recurring maintenance issues.

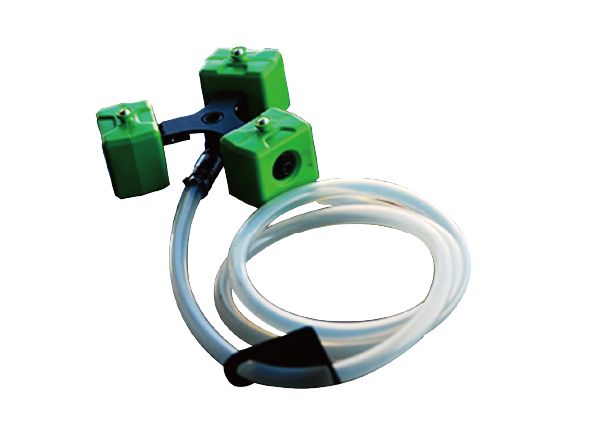

Oil mist may infiltrate into coolant pump systems, causing bacteria to grow, causing seals on motor pumps to deteriorate. Furthermore, unclean coolant corrodes metal surfaces, resulting in tool deterioration, accuracy issues, and a drop in component quality.

Circuit boards are damaged by dirt and extreme humidity, and cooling system filters get clogged. Airflow gets restricted when cooling system filters clog, which would result in system failure. Important electronic components such as drives, power supplies, displays, and control systems are protected by the cooling system. Temperatures will increase if the cooling system fails, causing electrical systems to be damaged and potentially cease to function correctly.

Furthermore, greater maintenance frequency results in more equipment downtime and productivity loss. Controlling oil mist effectively eliminates the need for repair and enables production to go as planned. As a result of the reduced need for replacement components and technician visits, money may be saved.

- You can ensure employee health

Last but not least, the oil mist collectors are capable of helping you to improve overall employee health. As oil mist touches the skin of employees, they will have to deal with the formation of dermatitis. This can lead you to rashes, itchy skin, and even skin cracks. On the other hand, you will be able to overcome blisters and reddish skin from forming. Skin conditions caused by oil mist can be serious. It is important to overcome them at all times. Otherwise, they can lead those employees to multiple complications. The oil mist collectors are capable of providing much-needed relief to the employees against oil mist.

Final words

Now you are aware of three prominent benefits that come along with oil mist collectors. You should also keep in mind that they will assist you to adhere to legal requirements as well. In fact, all the employers would make sure that employees are not exposed to oil mist, and an oil mist collector will help them with it.