What are the applications and benefits of drum skimmers

You can call drum skimmers as a quite versatile equipment available out there to consider. It is possible to use the drum skimmer and recover all spilled oil that is present on the water surface. One of the very first things that you will notice in a drum skimmer is the lightweight construction. On top of that, they are associated with a high efficiency and recovery rate as well. it is possible for you to use the drum skimmer and collect oil effectively during an oil spill. Due to the same reason, drum skimmers are quite popular in industrial applications.

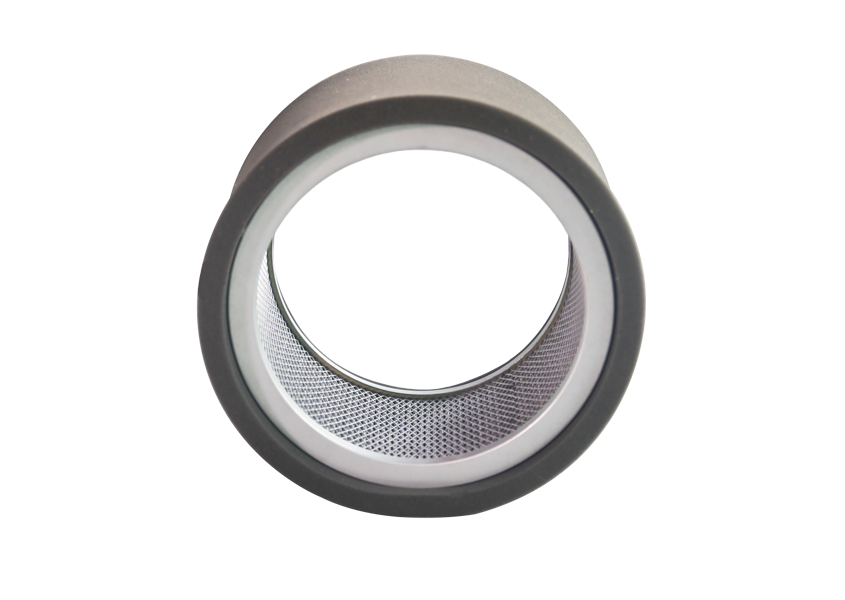

According to studies, it is identified that a drum skimmer is capable of recovering up to 95% of the oil. Even if you have 5% entrained water, you will be able to get the job done quite effectively. The oleophilic material and grooved surface can deliver a high recovery rate to you at the end of the day. This is much-effective when compared to other available drum skimmer technologies that you can find out there. Moreover, you can get a perfect experience out of them as you continue to clean up a large spill up effectively. Continue to read, and we will share more details with you on what drum skimmers are all about.

How does a drum skimmer work?

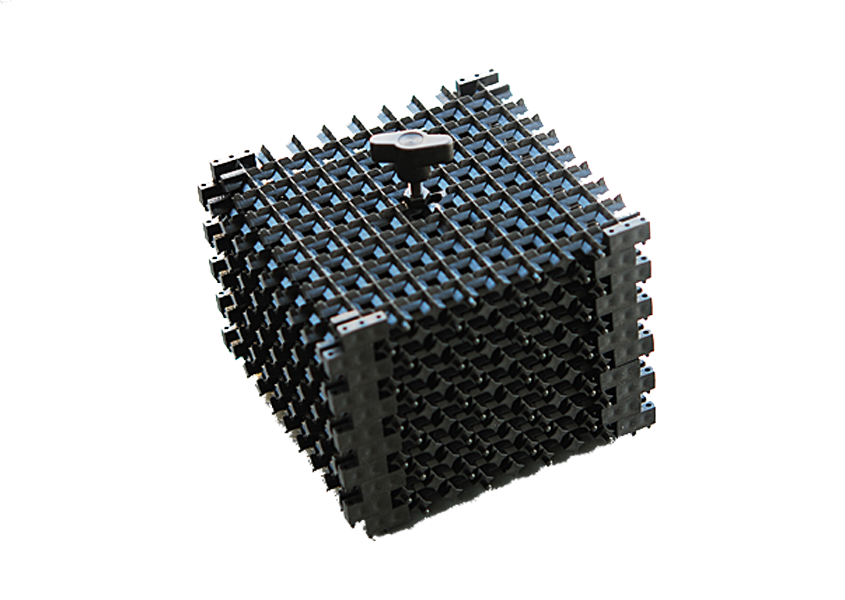

Drum skimmers are unusual in that the device's buoyancy is provided by the drum, which also removes oil from the water. They feature aluminum frames that are lightweight and quick to release in spill scenarios.

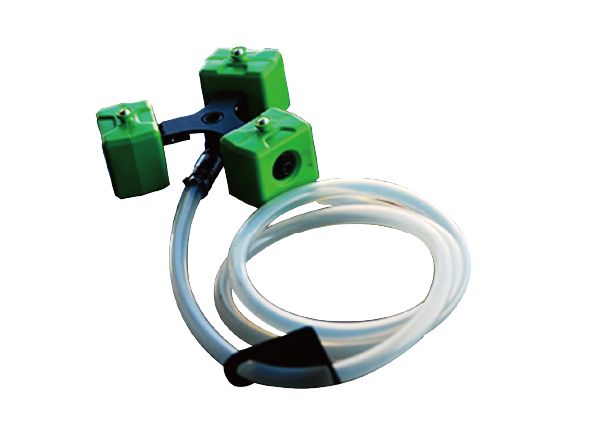

A drum skimmer is powered by either pneumatic or hydraulic sources. This power rotates the drum on the surface, removing oil from the spill area continually. The drum skimmer is also moved over the surface by the spinning action, covering a large spill area.

The collected oil is pumped out of the collecting trough to an offsite location, either on a ship or on land, by the power source. A drum skimmer may operate for hours without stopping the cleaning process as long even as power supply is turned on.

The revolving drum is the most important part of the drum skimmer. The drum's oleophilic substance draws oil. As it spins on the water's surface, its grooved surface generates a vast surface for oil to cling to the drum. Scrapers gather the oil, which is directed into the collecting basin by scrapers.

What are the benefits of drum skimmers?

Drum skimmers may function in as little as 75 millimeters of water, making them suitable spill response gear even in shallow seas along the coast. Drum skimmers are quite effective. They recover 95% of the oil, with just 5% of the water remaining in the collecting trough.

Any water used in the oil recovery process loses energy and capacity. Separating the water from of the oil in downstream operations adds to the clean-up expenses. Drum skimmers' great efficiency also cuts down on the time it takes to clear up a spill. Drum skimmers may be used in a variety of spill situations, thanks to the invention of groove surface on drum skimmers. Grooves help the drums recover a variety of oils, ranging from heavy bunker oils to light oils such as diesel.

Final Words

If you are impressed by the functionality of a drum skimmer, you may think about purchasing a one. It can provide a great overall experience to you as you try to get your industrial work done in an effective manner.