The Importance of Using a Drum Skimmer, Coolant Tank Skimmer, and Other Oil Skimmers for Machine CNC

The use of a coolant tank skimmer in machine shop settings offers a lot of benefits. Oil removal from a machine coolant tank initiates several aesthetic benefits including reducing the amount of smoke produced from the cutting tool that comes into contact with the coolant laden with oil.

Every time a machine gets shut down for a few days, there is a chance for oil to come to the coolant tank’s surface. The bacteria that live inside the coolant tank will then use up any dissolved oxygen present in the coolant mix. The presence of the oil layer on the surface speeds up this process. As a result, the odor-causing anaerobic bacteria thrive and produce that all-too-familiar smell similar to a rotten egg.

Contrary to common belief, the usual types of bacteria present in the metalworking fluids are not the culprits behind infections. But when the skin is broken, the bacteria that usually inhabit the skin might enter, leading to infection. The presence of carbonates and phosphates that increase the coolant’s alkalinity, however, may result in dermatitis. These impurities can be found in water used in the coolant mix.

The separation of the coolant and the oil also helps lower the costs of disposal. The disposal cost of oil-laden coolant is much more expensive compared to the disposal of oil itself. There are several instances when companies might be able to use this oil again somewhere else or they can also sell this for recycling. Ensuring that the coolant is oil-free also extends its effectiveness and usefulness, lowering the expenses on coolant replacement and maintenance.

Today, you can find numerous types of skimmers that are available in the market right now. Some of the most common types include belt skimmer, tube skimmer, disk skimmer, coolant tank skimmer, and drum skimmer. Every type of coolant skimmer offers its own set of pros and cons.

There are several important factors that you need to consider when looking for the right kind of oil skimmer to suit the appropriate application. Different factors including water temperature, water level fluctuation, the use of rust inhibitors, pH level, the specific amount of oil that needs to be skimmed, cost, and quality are all important considerations when choosing an oil skimmer.

Variable pH levels, high temperatures, and the use of rust inhibitors can all affect the ability of the skimmers to pick up oi. Many manufacturers of skimmers today use various materials for skimming mediums including stainless steel, poly blends, or plastic to match the specific solution where they will be used.

Today’s market is filled with a wide selection of skimmers. When shopping for a drum skimmer, a coolant tank skimmer, or any other oil skimmer for that matter, the quality of the unit you plan to purchase must always be the first thing to consider. Other crucial points of interest include motor design, construction materials, and the particular type of warranty being offered.

At the end of the day, always remember that choosing the right kind of skimmer can easily make or break your project. Always choose wisely.

Oil Mist Collectors

Economically efficient S series

Economically efficient S series

Smart Alert Flagship Series

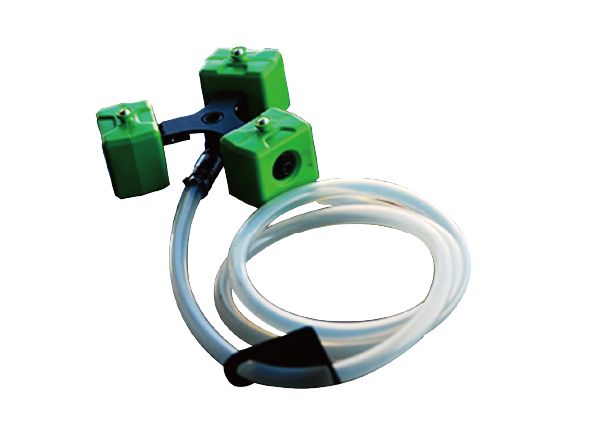

Smart Alert Flagship Series Oil Skimmer Ultra 90

Oil Skimmer Ultra 90 Oil skimmer Ultra 360

Oil skimmer Ultra 360 Oil skimmer Ultra 1200

Oil skimmer Ultra 1200 FC Series

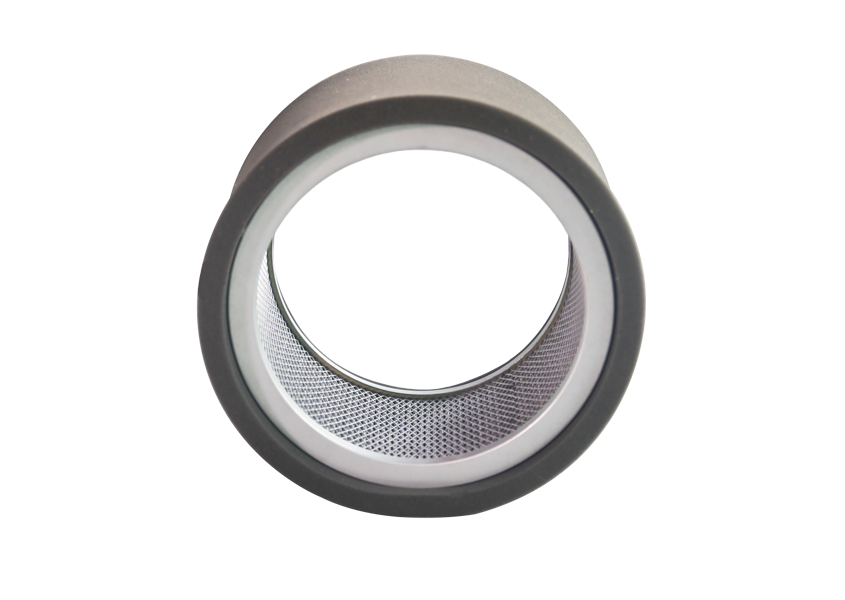

FC Series Precision filter FCG-105

Precision filter FCG-105 Precision filter FCG-105 AUTO

Precision filter FCG-105 AUTO S.T.P.M module

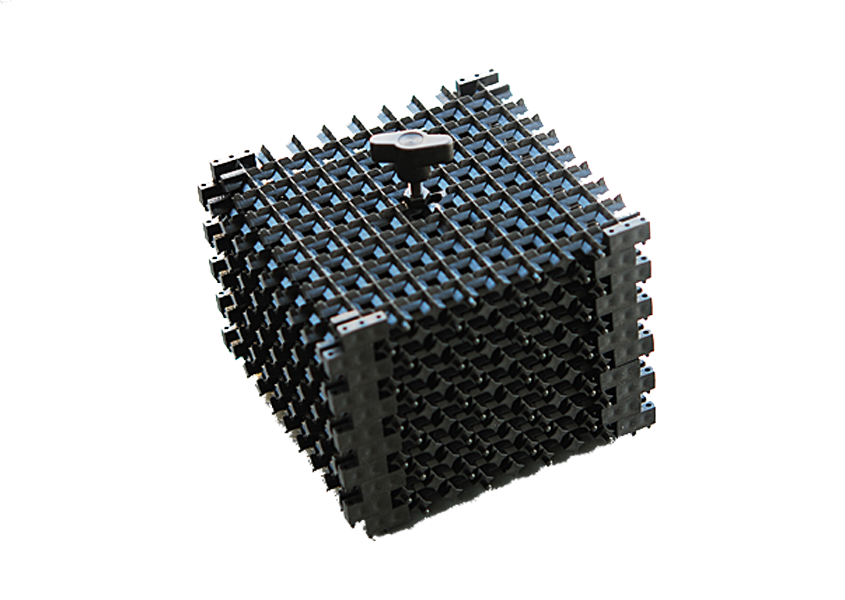

S.T.P.M module Floating Skimmer

Floating Skimmer Adjust Skimmer

Adjust Skimmer High efficiency filter tube

High efficiency filter tube Double open filter

Double open filter FCG series filter

FCG series filter